The flexibility and earthquake resistance of EARTH

This traditional walling system with a history of 6000 years beautifully illustrates the flexibility, ease of production and adaptability of earth architecture. Wattle and Daub is a composite wall building technique using tightly woven wooden sticks or split Bamboo known as the wattle, coated with a clay rich mix of chopped straw and soil, hair or animal dung, known as the daub. Many historic buildings include wattle and daub construction, and the technique is becoming popular again!

Category: Know your material

These are some of the ecological building techniques that we use at Made In Earth. There is a place for all these materials, and when applied with imagination, and in the right context, they create magic.

Tadelakt

The mystery and allure of LIME

There is probably no comparison to the sheer skill and patience required to create the luxurious feel of the Tadelakt. This sacred traditional practice that originates from Morocco, is passed on through word of mouth, from artisan to artisan. Tadelakt is created using limestone from the high Atlas mountains of Morocco. It has today, fascinated the imagination of modern artisans who are inspired by the fantastic walls of the Marrakesh Palaces that have remained virtually unchanged for centuries! The word ‘Tadelakt’ means ’to caress’ in Arabic.

Rammed earth

The strength and solidity of EARTH

The worldwide tradition of rammed earth construction has shown that it is possible to achieve strong majestic buildings that have

withstood the test of time. The grandeur of rammed earth has been expressed historically in houses, forts and palaces; even the great wall of China is largely built in earth! Rammed earth is a load bearing technique where earth is compacted in successive layers within a formwork.

Oxide & Lime Flooring

A sheen that accentuates with time

Modest in its appeal, ecologically conscious and affordable, this option of flooring is common in various parts of India. Although it has been around for ages, there has been a recent upsurge, with slight modifications in its making. Metal oxides are used to get a wide palette of colour options. Being mineral based, they are non-flammable, inorganic and do not emit hazardous compounds. This labour-intensive technique demands experienced attention in its application. It is durable, ages beautifully and is easy to maintain!

Natural Plaster

The breath-ability and aesthetics of EARTH

One important aspect of ecological construction is to guarantee a good ‘breathability’ of the building. The plasters being the first layer in contact with the outside and inside air, it plays an important role in the regulation of humidity, odors and temperature. Eliminating the need for a chemical paint over it, these renders can be sponge finished, smooth or trowel finished, rough or brush finished, hand finished, fibrous, plain, grainy, and together with natural colour pigments; the options are infinite!

Natural Paints

Clay everywhere

Natural paints, made with raw ingredients such as clay, marble, earth and mineral pigments can significantly improve the air quality in your building, positively impacting your health. Additives such as starch, casein, linseed oil used along with plant and mineral pigments result in less energy intensive finishes. These natural ingredients improve breathability of the wall, control moisture and eliminate potentially harmful chemicals present in conventional paints.

Hourdi block slab

A funny name for a Terracota slab

Coming into use in the early 20th century, structural terracotta originated in the Mediterranean and became increasingly popular in parts of India.

Hourdi blocks are made from natural clay that is baked in a kiln to create a hard, hollow component of the roof. The method of laying consists of placing the hollow blocks between prefabricated beams to form the slabs. The Hourdi Block is lighter in weight, speeds up the construction process and eliminates the need for shuttering as compared to the conventional Reinforced Cement Concrete system. It provides greater insulation at a relatively lesser cost.

Filler slab

Reduction in the use of slab concrete

A Filler slab is an Reinforced Cement Concrete slab that uses filler material embedded in it so that the weight of the slab and amount of concrete used comes down. Pots, Terracotta tiles, Coconut shells and bottles are some of the materials used in the filler slab system. The technique works on the concept of removing unnecessary concrete in the tension zone and filling it with lightweight and inexpensive materials. Revolutionised by Laurie Baker in India, these slabs increase the thermal comfort and add an interesting aesthetic to a space.

Earth Floors

The seamlessness of EARTH

Earthen floors were predominant mostly in Europe until the mid 14th century, usually of hard packed dirt topped off with a thin layer of straw for warmth and comfort. In modern times, most earthen floors are laid over tamped gravel, and then a mixture of clay, sand and sometimes fibres is spread with a trowel. The finished layer, once dry, is sealed with hardening oil or wax, giving it durability and lustre. Earthen floors offer great insulation, come in a variety of colours, have low environmental impact and are relatively affordable.

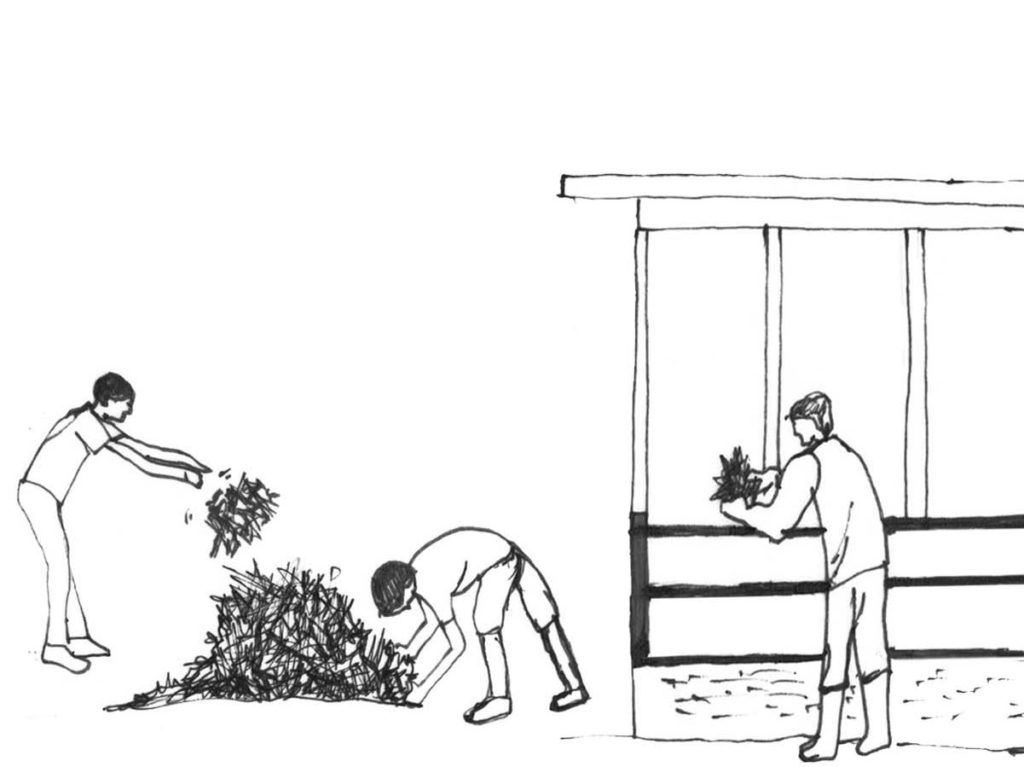

Earth and Straw

The climatic adaptability and comfort of EARTH

Heiress of the wattle and daub, the straw & clay technique is spreading quickly, especially in Europe, due to its remarkable thermal property and the comfort that it can bring to our interiors. It’s main ingredient; straw, is available virtually everywhere (wheat, rice, hemp straw, etc) and when sourced locally, makes this wall filling material one of the most ecological.

Compressed earth bricks (CEB - CSEB)

The engineered modern age EARTH

Compressed Stabilised Earth Blocks - The soil, raw or stabilized, is slightly moistened, poured into a steel press and then compressed either with a manual or motorized press. It seems that the first attempts at Compressed Earth Blocks (CEB) were tried in France, in the early years of the 19th century: The architect Francois Cointeraux, around 1803, precast small blocks of rammed earth. He used hand rammers to compress humid soil into small wooden moulds which were held with the feet.

Arches Vaults Domes

The monumentality and geometric wonder of EARTH

Popular in almost all historic buildings of the ancient world are arches, vaults and domes - and we have the Romans to thank for it ! The forms they used to span basilicas, baths and aqueducts centuries ago, as been abandoned and replaced with steel and cement intensive.

Today, these forms are proving to be an eco-friendly alternative to conventional Reinforced Cement Concrete, that can span large spaces while giving monumental character. This labour intensive is a display of masonry craftsmanship at its best!

Adobe

The affordability & timelessness of EARTH

Earth is the oldest and has been the most essential building material over centuries. The tradition of making sun dried raw earth bricks popularly known as adobes goes back to the beginning of human society. Adobe is versatile, viable and provides great flexibility in the construction of earth buildings. These bricks are fireproof, non toxic and has an excellent thermal performance. Adobe buildings can be found across continents where it has been spontaneously and continuously adapted by people of different cultures for housing as well as monumental structures.